In the worst case, it can cause equipment to break or malfunction to the point that downtime is necessary. It can also lead to increased costs due to extra maintenance and operator working hours. Using one incorrectly can cause machinery to suffer undue wear and operate less efficiently.

The Effects of Improperly Applied and Worn AirlocksĪirlocks, while simple, are an indispensable part of certain material conveying and processing operations. In general, open-ended units are better suited for easy-flowing non-abrasive materials and closed-ended setups work best for materials that may have issues with flowing smoothly. Another thing to discuss is whether you will need an open-end or closed-end rotor.

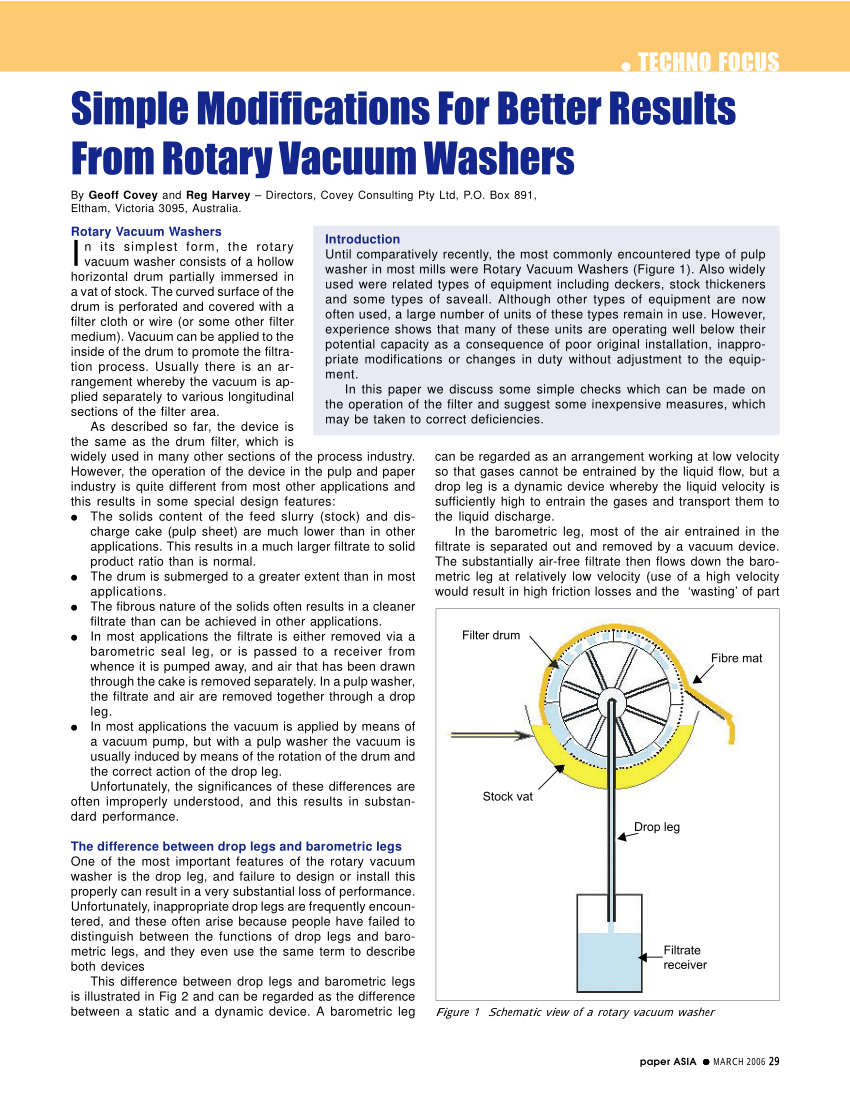

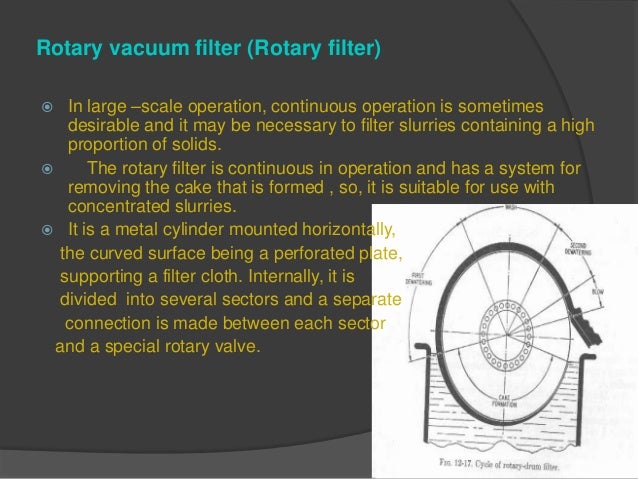

FUNCTION OF ROTARY VACUUM FILTER PROFESSIONAL

It’s important to talk with a professional to figure out the optimal setup for the specific materials you’ll be handling. Heavier materials and materials that flow quickly are not as greatly affected by the number of vanes and subsequent pocket size. Larger pocket size is ideal for processing larger materials or materials that tend to stick or pack together when compressed. As the number of blades increases, however, the size of the pockets between them decreases. A valve with more vanes tends to have greater sealing ability than one with less. A six-vane rotor has six metal blades attached to the shaft, an eight-vane rotor has eight, and so on. The rotor assembly in a rotary airlock valve is sometimes referred to as a the paddle wheel, impeller, or flipper. The rotor assembly in a rotary airlock valve consists of a set of blades welded to a rotary shaft. This pressure or vacuum difference must be maintained within the valve for proper function. Material is moved continuously through the presence of a constant air pressure between the ports. This allows the materials to travel downward through the valve from the inlet to the outlet port while restricting the airflow. In an airlock valve, air is sealed (locked) between the inlet and outlet ports. The material being handled enters the pockets through the inlet port before rotating around inside the valve and then exiting through the outlet port. The vanes, or metal blades, of a rotary airlock valve turn (rotate) during operation. What Happens Inside a Rotary Airlock Valve It’s important to remember that not all rotary valves are necessarily rotary airlock valves – but virtually all rotary airlocks are rotary valves. Though simple, the rotary airlock valve is a critical component to the efficiency of a conveying system. Used in both pressure style and vacuum style pneumatic conveying systems, these valves serve as a “lock” to prevent air loss while simultaneously performing vital material handling functions. Rotary airlock valves are also called rotary feeders, rotary valves, or just rotary airlocks.

0 kommentar(er)

0 kommentar(er)